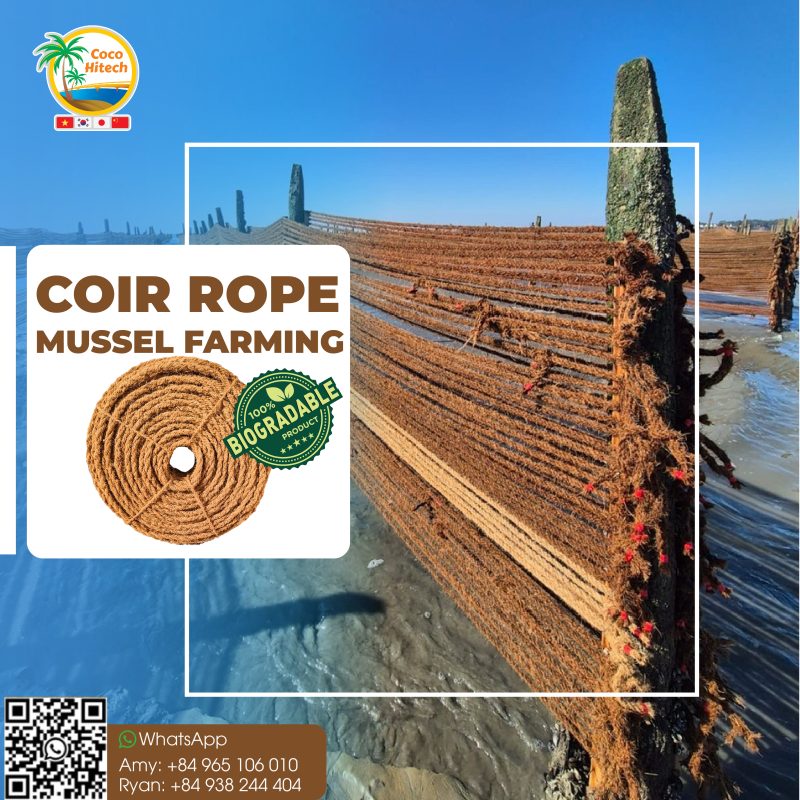

Adopting coir rope for mussel farming is becoming the industry standard for producers aiming to reduce environmental impact while maintaining high yields. As regulatory pressure mounts to eliminate plastic from our oceans, finding a reliable coconut coir rope manufacturer is essential for modern aquaculture. This guide explores why biodegradable coir rope for sustainable mussel spat collection is the superior technical choice for your farm.

Table of Contents

Table of Contents

- Understanding the Biodegradability of Coir Rope in the Marine Ecosystem

- How Mussel Larvae Utilize the Rough Texture of Coconut Fiber for Settlement

- The Role of Lignin in Providing Saltwater Stability for Natural Fiber Ropes

- Reducing Ocean Plastic Pollution by Choosing Coir Over Synthetic Alternatives

- Advantages of Compostable Substrates for a Circular Economy in Aquaculture

- Using Coir Substrates for Shellfish Restoration and Sustainable Fisheries

Understanding the Biodegradability of Coir Rope in the Marine Ecosystem

The shift toward sustainable aquaculture requires materials that harmonize with the ocean rather than pollute it. Coir, derived from coconut husk fiber, offers a unique biological profile that synthetic ropes cannot match.

The Science Behind the Decomposition of Plant Based Fibers in Oceans

Unlike plastics that fragment into harmful micro-particles, plant fibers undergo organic decomposition. When submerged, the cellulose in the rope interacts with marine bacteria.

This process is natural and non-toxic. As the rope breaks down, it releases organic matter that integrates seamlessly into the marine food web. This ensures that the farming process leaves no chemical footprint.

Timeline of Degradation for Coconut Husk Material in Saltwater

The rate of decomposition in saltwater is a critical factor for farmers. You need the gear to last through the grow-out cycle but degrade shortly after.

Typically, biodegradable aquaculture-grade coir maintains structural integrity for 12 to 24 months. This aligns perfectly with the harvest cycles of many mussel species, preventing premature breakage while ensuring disposal is eco-friendly.

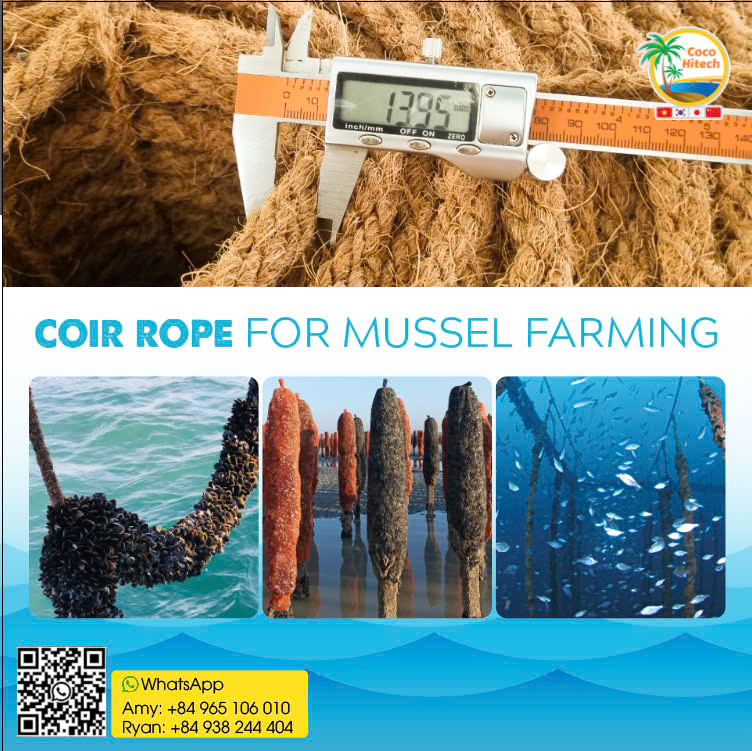

How Mussel Larvae Utilize the Rough Texture of Coconut Fiber for Settlement

The success of a harvest depends heavily on the initial catch. Using coir rope for mussel farming significantly improves settlement rates due to its physical properties.

Why High Lignin Content Makes Coir Superior to Other Plant Fibers

Fibers from Cocos nucifera contain significantly more lignin than jute, cotton, or hemp. Lignin is a natural polymer that provides rigidity and protection against rotting.

High lignin content coir creates a natural barrier against rapid microbial attack. This inherent saltwater resistance is why coir is the preferred choice for marine applications over softer natural fibers.

Reducing Ocean Plastic Pollution by Choosing Coir Over Synthetic Alternatives

The aquaculture industry is under scrutiny for its contribution to ocean waste. Switching to natural fiber ropes is the most impactful change a farm can make.

Eliminating Microplastics Shedding Associated with Nylon and Polypropylene

Every time a synthetic rope rubs against a longline or buoy, it sheds microscopic plastic particles. This marine microplastic pollution is ingested by the very shellfish being farmed.

Using coir eliminates this risk entirely. It ensures that the final seafood product is free from plastic contaminants derived from the farming gear itself.

Reducing Waste Management Costs for Sustainable Mussel Farms

Disposing of industrial plastic waste is expensive. Landfill taxes and transport fees cut into profit margins.

By utilizing compostable gear, farms can significantly lower these costs. Local composting facilities often accept these materials at a fraction of the cost of industrial waste processing.

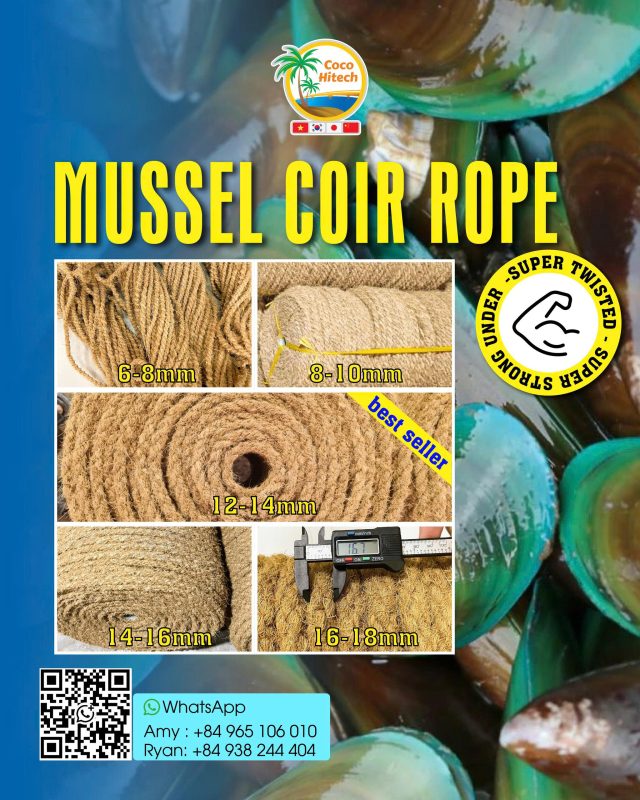

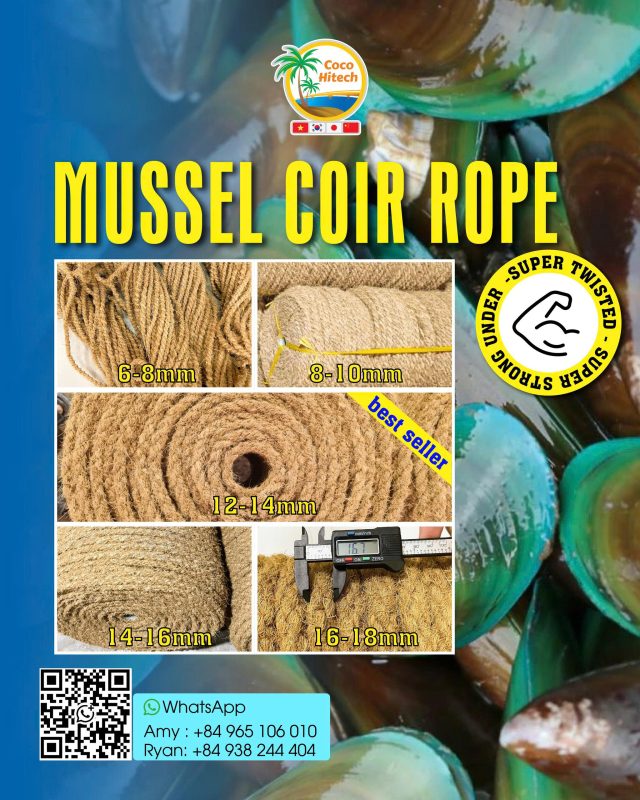

Top of coconut fiber manufacturer in Viet Nam: COCO HITECH

-

Specialized manufacturer of mussel coir rope

-

Consistent export quality for EU & Korean markets

-

Stable supply for large-scale aquaculture projects

-

Professional packaging & export documentation

-

Custom production according to farming system requirements

COCO HITECH TEAM:

- 대표: Mr.Ryan (Vietnam): +84 938244404(Kakaotalk, Wechat, Whatsapp)

- Amy (English) : +84 965106010 (WhatsApp, Kakao, Line)

- Ryna ( 한국 영업 담당자 ): +84 0364775030

- Vi (中文)+84397317401| 微信ID: Nttv0608

- Website: https://cocohitech.com

- Website: https://kr.cocohitech.com(Korea)

- Website: https://cocohitech.jp/ (Japan)

- Youtube: https://www.youtube.com/watch?v=X7uwnNDKJ4M&t=70s

- Instagram: https://www.instagram.com/cocohitech/

COCO HITECH JSC

261-263 Phan Xich Long Street, Ward 2, Phu Nhuan District, Ho Chi Minh City, Vietnam Tel: +8493 8244404 (Vietnam) Email: info@cocohitech.com https://cocohitech.com | https://coconutpowder.net