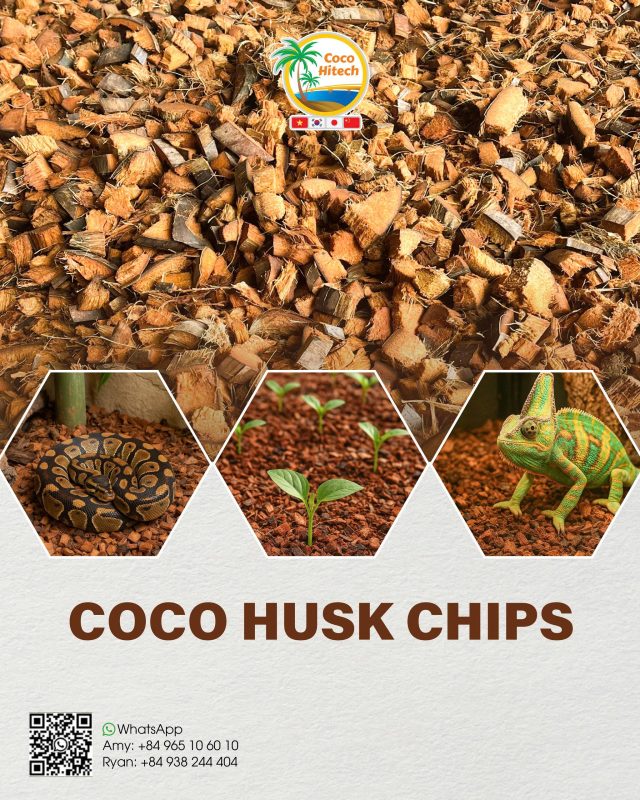

Producing coco chips (also called coconut husk chips) involves cutting and drying the outer husk of coconuts into small uniform pieces. These chips are widely used in horticulture, orchid growing, hydroponics, and soil conditioning because of their excellent water retention, aeration, and biodegradability.

Here’s a step-by-step guide to the production process:

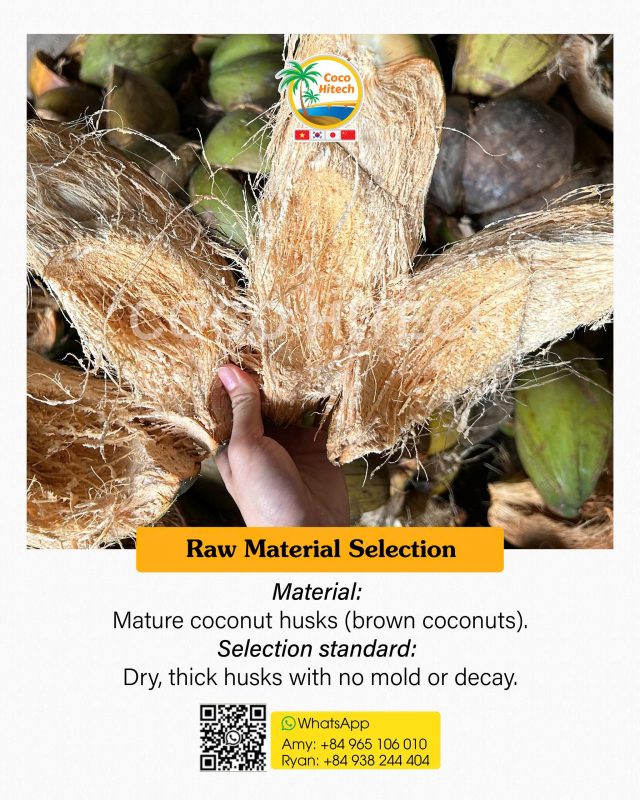

🌴 1. Coco husk sourcing

- Material: Mature coconut husks (brown husks are preferred — they contain more lignin and are more durable).

- Source: From coconut processing factories or directly from coconut farms.

- Quality check: Ensure husks are free from mold, rot, or contaminants.

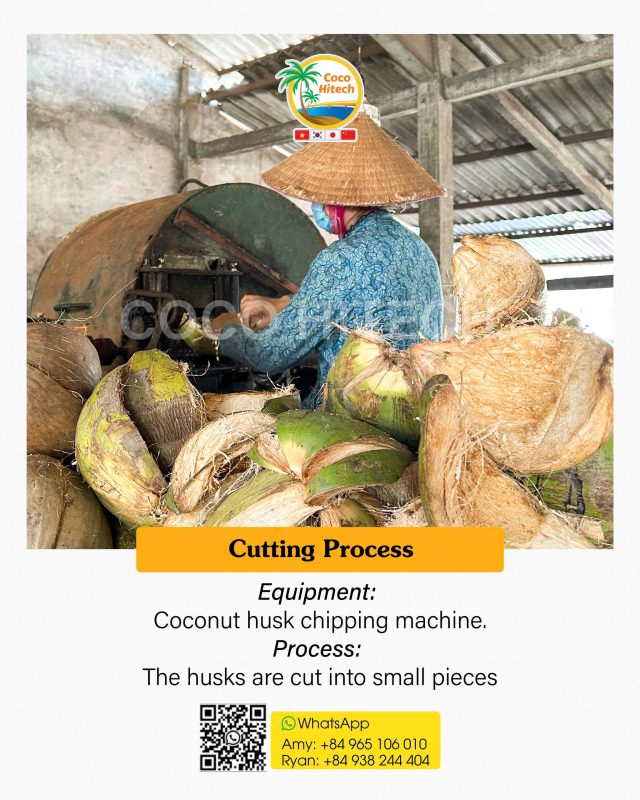

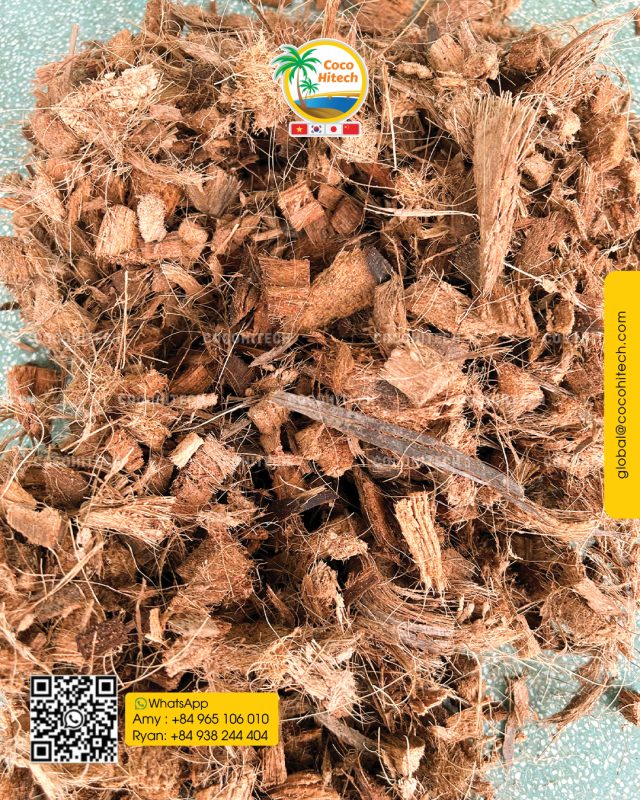

🔪 2. Coco husk Cutting

- Machine used: Coconut husk chipping machine or coconut cutter.

- Process: Husks are fed into the machine and chopped into small, even-sized pieces.

- Chip size options:

- Small: 5–10 mm

- Medium: 10–20 mm

- Large: 20–30 mm

- (Sizes can be customized depending on customer requirements)

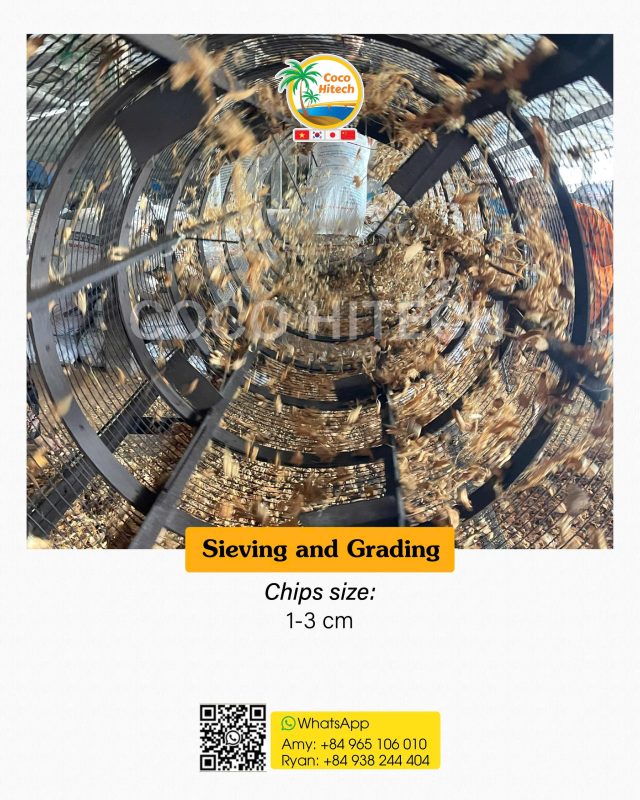

🧺 3. Sieving

- Separate fine dust and fibers from the chips using a vibrating screen or rotary sieve.

- You can reuse the fine dust (for coco peat production) and long fibers (for ropes or mats).

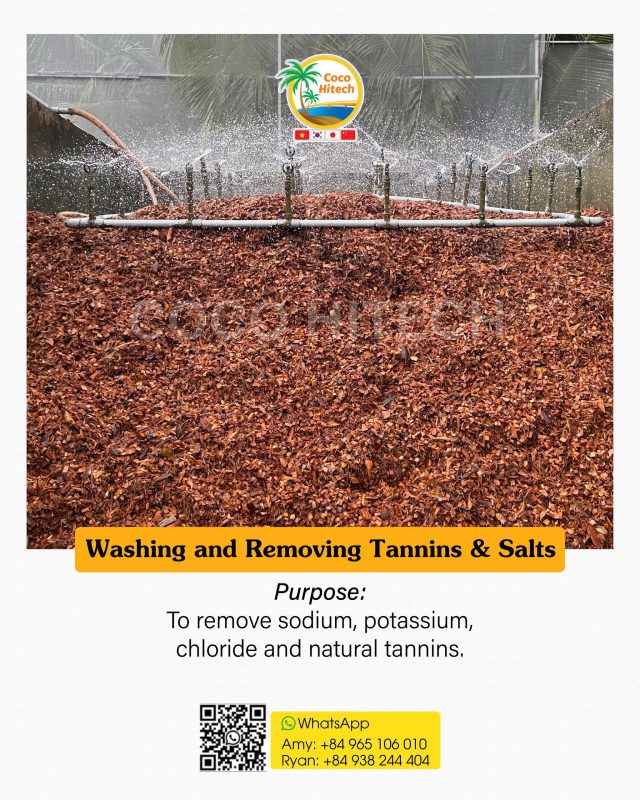

💧 4. Washing (if required)

- Chips are often washed with fresh water to reduce EC (electrical conductivity) — removing excess salts.

- After washing, drain and press to remove extra water.

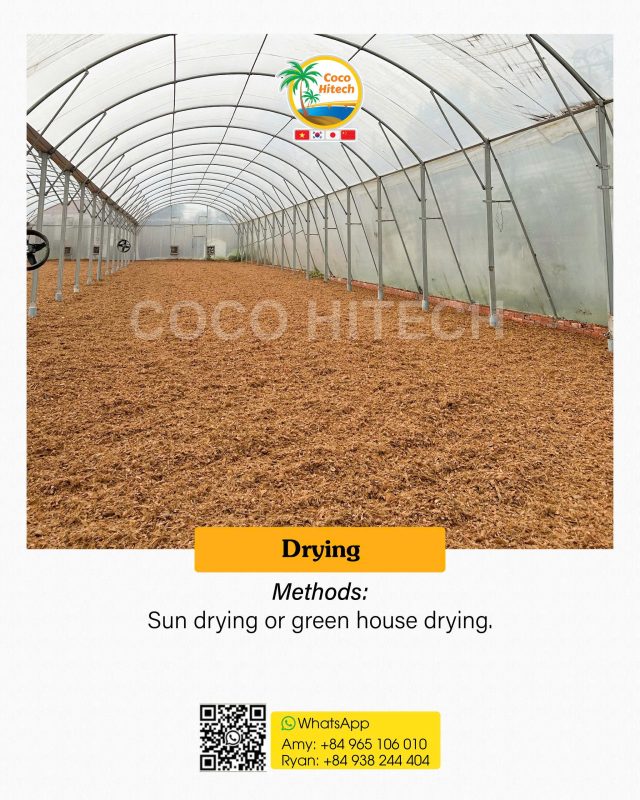

☀️ 5. Drying

- Sun drying or hot-air drying to reduce moisture content to below 15%.

- Proper drying prevents mold growth during storage and transport.

📦 6. Compression & Packing

- Dried coco chips can be:

- Loose-packed in PP bags (5–25 kg), or

- Compressed into blocks/bricks (like coco peat blocks) using a hydraulic press.

- Typical block: 5 kg (30 × 30 × 10–12 cm).

- Wrap and label according to export standards.

🚢8. Storage & Export

- Store in a dry, well-ventilated warehouse.

✅ Coco chips specifications (Typical Export Grade)

| Parameter | Specification |

| Size | : 10–30 mm |

| Low EC | : ≤ 1.0 mS/cm (washed), high EC: ≥ 1.0 mS/cm |

| pH | : 5.5–6.8 |

| Moisture | : 30-40 % |

| Impurities | : < 3% |

COCO CHIPS MANUFACTURING AND EXPORTER

COCO HITECH is proud to be the Top of coco chips manufacturer in Viet Nam. We supply coco chips, coco peat, coco peat block, coco peat bag in Viet Nam. For further information, feel free to contact us:

- Sales Director: Mr.Ryan (Vietnam): +84 938244404(Kakaotalk, Wechat, Whatsapp)

- Amy (English) : +84 965106010 (WhatsApp, Kakao, Wechat, Line)

- Ryna ( 한국 영업 담당자 ): +84 0364775030

- Vi (中文)+84397317401| 微信ID: Nttv0608

- Website: https://cocohitech.com

- Website: https://kr.cocohitech.com(Korea)

- Website: https://cocohitech.jp/ (Japan)

- Youtube: https://www.youtube.com/watch?v=X7uwnNDKJ4M&t=70s

- Instagram: https://www.instagram.com/cocohitech/

COCO HITECH JSC

261-263 Phan Xich Long Street, Ward 2, Phu Nhuan District, Ho Chi Minh City, Vietnam Tel: +8493 8244404 (Vietnam) Email: info@cocohitech.com https://cocohitech.com | https://coconutpowder.net