Finding a specialized coco peat block manufacturer in Vietnam is critical for international distributors seeking consistent quality and scale. As global demand for sustainable growing media rises, buyers often struggle to locate partners who can deliver low-salinity substrates compliant with strict agricultural standards. This guide provides a practical roadmap for sourcing premium coir directly from the Mekong Delta.

Table of Contents

Selecting a Reliable Coco Peat Block Manufacturer in Vietnam for Bulk Supply

Securing a partnership with a dependable factory requires more than just an internet search. You must verify that the supplier controls the entire supply chain, from raw husk collection to final compression. Genuine Vietnam coco peat exporters often own facilities in raw material hubs rather than operating solely as trading intermediaries.

When vetting potential partners, prioritize those offering bulk low EC coco peat blocks from Vietnam manufacturers. A reliable factory will be transparent about their washing processes and aging timelines. Transparency is the only way to ensure the substrate will not damage sensitive root systems upon arrival.

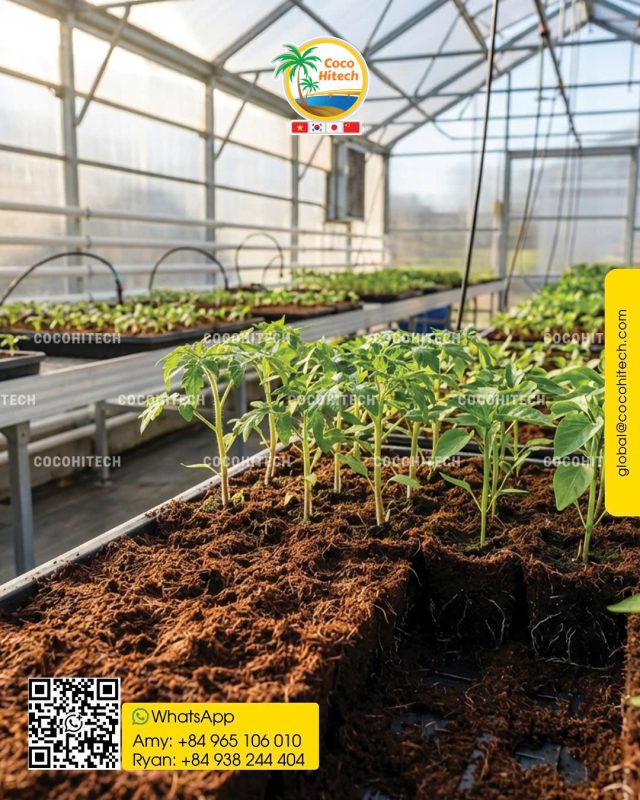

Furthermore, assess the manufacturer’s production capacity. Large-scale greenhouse operations require assurance that their supplier can handle peak season demands without compromising on the curing process. Ask for video evidence of their drying yards and compression machinery to validate their claims.

Advantages of Coconut Coir Pith Production in the Mekong Delta and Ben Tre Province

The geographical location of a factory significantly impacts the quality of the final product. The Mekong Delta coconut processing industry benefits from an abundance of fresh water, which is essential for washing out natural salts found in raw coir. Factories located near the sea often struggle to achieve low salinity levels naturally.

Specifically, the best coconut mulch suppliers in Ben Tre province Vietnam utilize the region’s vast network of rivers to transport raw materials efficiently. This region is famous for high-yield Cocos nucifera trees, which produce thick husks rich in lignin. This natural durability translates into a growing medium that maintains its structure longer.

Additionally, sourcing from Ben Tre ensures a consistent supply of fresh husks. Unlike regions that rely on aged husks from other industries, Vietnam’s dedicated coir industry processes fresh material. This results in a cleaner product with fewer pathogens and a more consistent golden-brown color preferred by the US market.

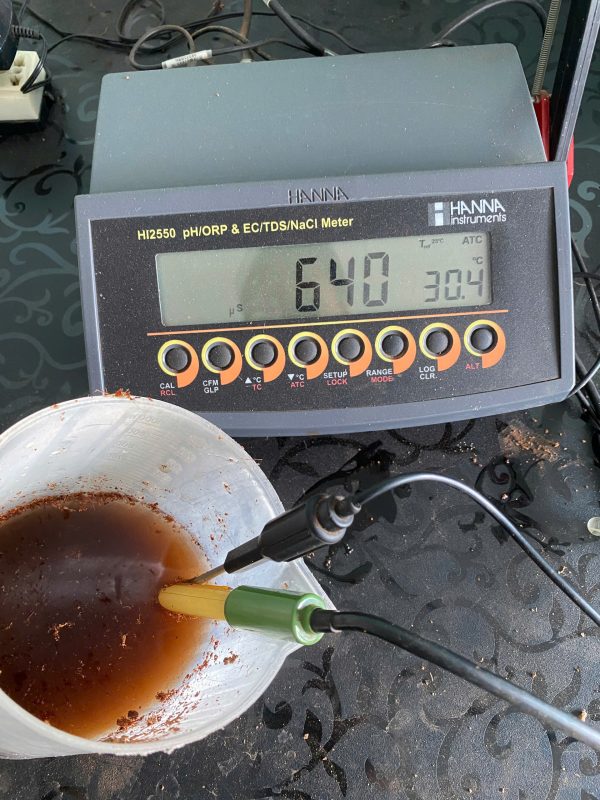

Verifying Low EC Levels and Expansion Volume in the Standard 5kg Block

EC testing: We recommend sourcing EC < 0.5 coco peat for sensitive crops like berries and cannabis. High salinity locks out nutrients, preventing plants from absorbing essential minerals. Reliable manufacturers wash the pith repeatedly to lower EC levels before compression.

Expansion ratio. A standard wholesale coco coir pith 5kg blocks should demonstrate a compressed substrate 5:1 ratio. This means that once hydrated, the block breaks down effortlessly into a usable volume. Ideally, you should expect an expansion volume 15 to 17 liters per kilogram of weight.

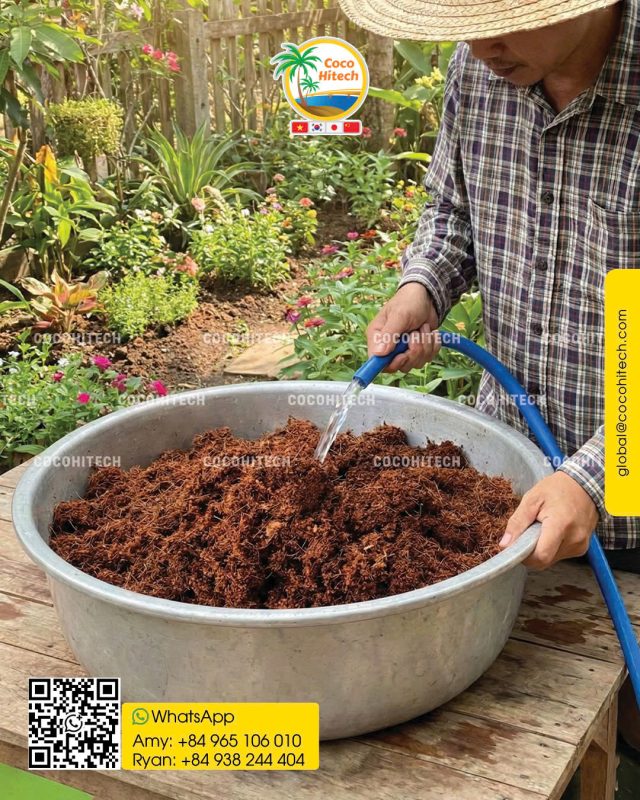

Ensuring Proper Washing and Drying for Hydroponic Medium Suitability

To prepare a greenhouse growers substrate, the raw pith must undergo rigorous aging and washing. This process removes tannins and reduces the sodium and potassium content. If these elements remain high, they can interfere with the cation exchange capacity coco coir naturally possesses.

A high-quality substrate will stabilize at a pH 5.5–6.5 growing medium range. This acidity level is optimal for nutrient uptake in soilless cultivation systems. Buyers should request recent lab reports from the manufacturer confirming these pH levels are consistent across different batches.

Finally, the drying method affects pricing and quality. Organic hydroponic coco peat block pricing often reflects whether the product was sun-dried on concrete floors or directly on the ground. Concrete drying prevents contamination from soil pathogens and weed seeds, making it the superior choice for export-grade material.

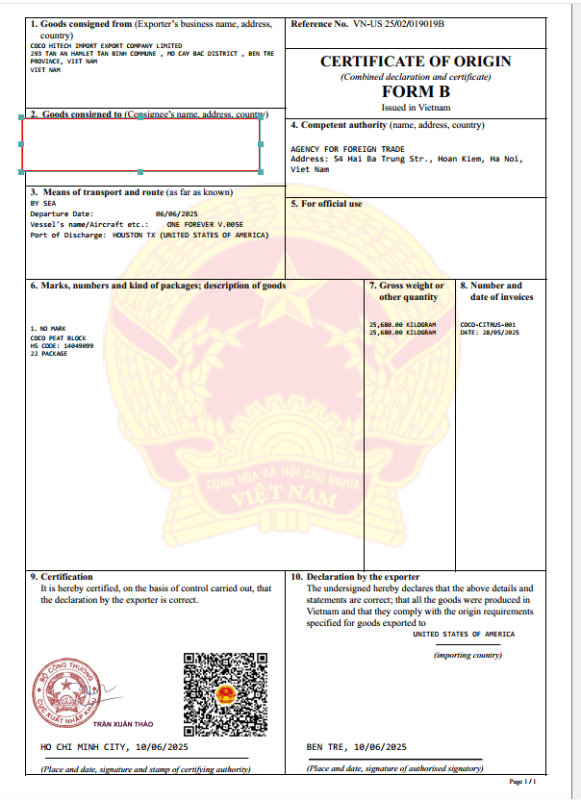

Navigating International Import Regulations and Phyto Sanitary Certificate

sanitary Documentation

The product must also meet low moisture standards, usually below 20%, to prevent mold growth during transit. Shipping high-moisture organic material in a closed container for weeks creates a breeding ground for fungus. Professional exporters use moisture meters to certify levels before loading.

Additionally, confirm that the pallets used for shipping are ISPM-15 compliant (heat-treated wood). Using non-compliant wood packaging can lead to the rejection of the entire container at the US port of entry. Experienced exporters in Vietnam will have these protocols integrated into their standard operating procedures.

COCO HITECH – Leading Coco Peat Block Manufacturers in Vietnam

COCO HITECH (Vietnam) is a major Vietnamese manufacturer and exporter of coco peat blocks, coir substrates, coir fiber, mats, and other coconut products. Based in Ben Tre — the heart of Vietnam’s coconut processing region — COCO HITECH supplies both washed (low EC) and unwashed coco peat blocks for export and global markets.

If you have any inquiries feel free to contact with our dedicated sales team:

- 대표: Mr.Ryan (Vietnam): +84 938244404(Kakaotalk, Wechat, Whatsapp)

- Lan ( 한국 영업 담당자 ): +84 969273598| Kakaotalk ID: hoailan98

- 电话 (阮秀钗) +84 933320776| 微信ID:TuTram1008

- Han(日本) : +84 974819071I Line: cocohitech.info

- Vi (中文)+84397317401| 微信ID:NTTV_0608

- Amy (English) : +84 965106010(WhatsApp, Kakao, Line)

- Website: https://cocohitech.com

- Website: https://kr.cocohitech.com(Korea)

- Website: https://cocohitech.jp/ (Japan)

- Youtube: https://www.youtube.com/watch?v=X7uwnNDKJ4M&t=70s

- Instagram: https://www.instagram.com/cocohitech/

COCO HITECH JSC

261-263 Phan Xich Long Street, Ward 2, Phu Nhuan District, Ho Chi Minh City, Vietnam Tel: +8493 8244404 (Vietnam) Email: info@cocohitech.com https://cocohitech.com | https://coconutpowder.net